Manufacturing Service System

Manufacturing Service System

- Categories:About Seagull

- Time of issue:2021-08-26 16:15:43

- Views:0

Laboratory

The laboratory covers an area of about 800 square meters and is fully functional. It is equipped with sophisticated testing equipment and professional engineering and technical personnel. The mechanical testing capabilities include tightness testing, high temperature and high pressure strength testing, flow testing, anti-use strength, and Load strength, life test, anti-siphon test, etc., and obtained the IAPMO laboratory's in-plant test laboratory accreditation in 2006, so that Seagull has unparalleled advantages in UPC/cUPC certification projects! In 2009, it passed the AB1953 (California Water Pipeline Products Low Lead Act) authorized by the IAPMO laboratory of the United States and the EPA high efficiency and energy saving certification test and obtained the ability recognition certificate. The long certification history and rich certification experience provide a strong guarantee for Seagull's products to enter the international market.

Since its establishment, laboratory management has been gradually improved, testing capabilities have been continuously improved, and a complete and effective management system has been formed. In order to improve laboratory management and technical capabilities, and ensure the accuracy of test results, CNAS-CL01:2006 ( ISO/IEC17025:2005) "Testing and Calibration Laboratory Competence Accreditation Criteria" management system. And in February 2011, it obtained China National Laboratory Certification.

PVD (VT–3000)

Low-temperature arc vapor deposition machine VT3000 (English abbreviation: LTAVD---VT3000) is mainly used for metal and plastic surface treatment. It can process and produce products with complex surface processing technology under low temperature conditions. The quality is stable, and the coating and coating The color is uniform, hard and reliable.

Equipped with an external LCD touch screen computer, indicator lights and various control buttons to achieve real-time monitoring of production, making the operation more user-friendly; the unique interlocking system of the equipment can effectively protect and alarm automatically, guaranteeing people The safety and reliability of, machines, products, etc.; the humanized visual operation interface can clearly and clearly assist in quickly discovering and solving equipment abnormalities.

Zinc alloy plating line

The zinc alloy electroplating line is mainly responsible for the electroplating surface treatment of zinc alloy bathroom hardware products, faucet shells, faucet handles, bathroom accessories, door handles, etc. It has skilled plating processing technologies such as chromium, nickel, and copper. The quality of the plating products is excellent and popular in China. The praise and trust of foreign customers. PLC programming fully automatic gantry electroplating line, with a total length of 120 meters, electroplating process parameter control, the whole process adopts microcomputerization, real-time collection, monitoring, automatic alarm reminder, and an independent electroplating technology laboratory, which can sample the electroplating solution every hour . In terms of energy saving and emission reduction, a heavy investment is made in wastewater treatment stations. After electroplating wastewater is concentrated and treated, it reaches 100% of the standard and can be recycled.

Electroplating gantry line and spraying line

The electroplating gantry line and the spraying line are professional production lines for product surface treatment, multi-color powder spraying and liquid paint spraying. The company has complete testing equipment and mold manufacturing equipment. It can design and make samples of various colors and appearances according to customer requirements. plastic products. Seagull has mastered not only the types and processes of copper, nickel, and chromium plating, but also advanced and high value-added electroplating types and processes such as imitation stainless steel surface plating and ion vacuum coating (PVD).

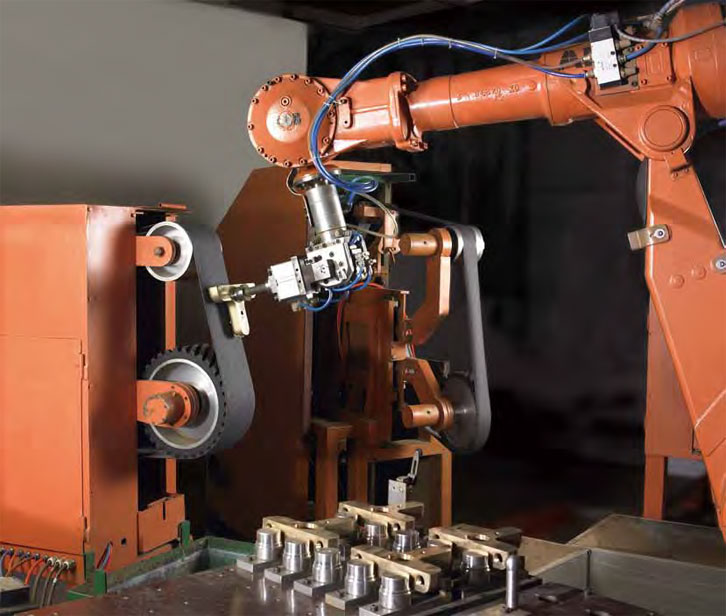

Robot automatic grinding and polishing

Seagull introduced the ABB-ROBOT4400 robot and successfully applied it to the polishing of sanitary products, turning the polishing workshop into a modern workshop with high automation and real-time information system. The use of robot grinding and polishing instead of manual grinding and polishing reduces the personal injury caused by the high dust and high noise environment of grinding and polishing, reduces the labor intensity of employees, and improves productivity, product quality, production reliability and safety.

CNC

The production technology mainly uses advanced CNC (computer numerical control) machining centers, numerical control machine tools, etc. as the main equipment, and is equipped with a tool magazine that can automatically change tools, which can adapt to a small amount of flexible production. Using this type of equipment and technology, after the workpiece is clamped once, the CNC system can control the machine tool to automatically select and replace the tool according to the process (programmable), and automatically change the spindle speed, feed and the motion path of the tool relative to the workpiece. The processing of multiple processes of the workpiece, that is, the products completed by multiple processes in the general processing technology can be concentrated in one process to complete the clamping. It integrates flexibility, intelligence, high precision, and reproducibility. It is especially suitable for Products with strict dimensional tolerances, large machining allowances, large product volume requirements, and strict geometric tolerances.

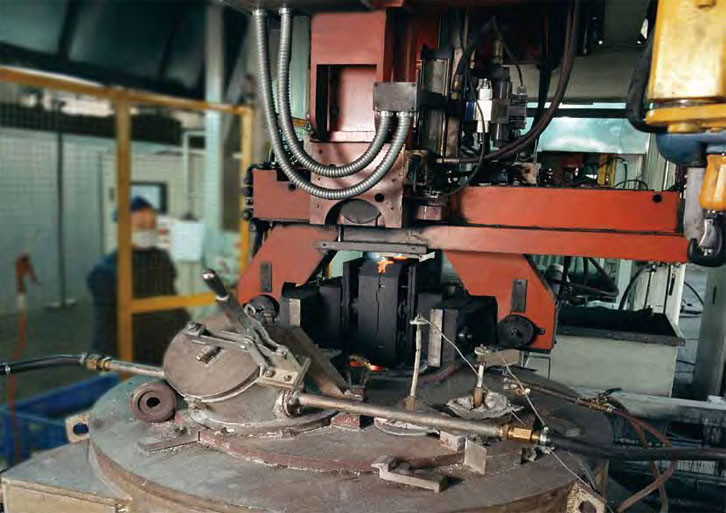

Low pressure casting

Low-pressure casting is a process technology in which molten metal fills the mold cavity from bottom to top under the action of low pressure (20-60kPa), and solidifies to form castings. It has the characteristics of stable filling, good casting formability, and dense structure. The quality and yield of castings have the incomparable advantages of sand casting and gravity casting, which can meet the quality standards necessary for high-end large products. The brass casting equipment and technology introduced by the company, the casting process adopts PLC control, which has high automation and production efficiency, low labor intensity, energy saving, and less environmental pollution.

Scan the QR code to read on your phone

Copyright: Guangzhou Seagull Kitchen And Bath Products Co., Ltd.

Guangzhou Seagull Kitchen And Bath Products Co., Ltd.

+86 20 8489 6096

+86 20 8489 6096

Message

Message